Infrared thermal imaging cameras

Fluke infrared thermal imaging cameras provide you with high-quality thermal images for industrial inspection. You can discover faults and failures before they become a problem – and enjoy the ease of a high-resolution, high temperature sensitivity, rugged thermal camera, ready for the toughest industrial environments.

By noting temperature changes, thermal imaging helps you find leaks, cut costs, and use energy more efficiently.

Handheld thermal cameras are best for preventive maintenance, electrical inspections, and frontline troubleshooting. While articulating thermal cameras are best for when you need pinpoint accuracy from both near and far, from electrical utilities to research and development. And mounted thermal cameras or infrared scanners are the strongest in the bunch, ideal for research, science and engineering applications allowing for continuous infrared data collection.

Find the best thermal camera for your needs

Select the right thermal camera to suit the inspections, maintenance, and troubleshooting you need to conduct.

TiS75+ Thermal Camera

Features 384 x 288 infrared resolution, touchscreen, video recording, dew-point calculation.

Fluke TiS55+ Thermal Camera

256 x 192 IR resolution, asset tagging, voice annotation, IR-PhotoNotes and touchscreen IR-Fusion.

Fluke TiS20+ / TiS20+ MAX Thermal Imaging Camera

Ideal for HVAC, mechanical and electrical inspections. 2-meter drop tested, IP54 water/dust...

Fluke Ti480 PRO Infrared Camera

Get a leading-edge visual infrared experience in a professional 640 x 480 thermal imager.

Fluke TiX580 Infrared Camera

Get stunning 640 x 480 resolution thermal images and surprising affordability.

Compact Fluke PTi120 Pocket Thermal Camera

A handheld thermal camera so easy to use you can empower your entire team.

Fluke RSE300 Mounted Infrared Camera

A high performance, 320 x 240 infrared camera. Perfect for streaming and analyzing thermal data,...

Fluke RSE600 Mounted Infrared Camera

A high performance, 640 x 480 infrared camera. Perfect for streaming and analyzing thermal data,...

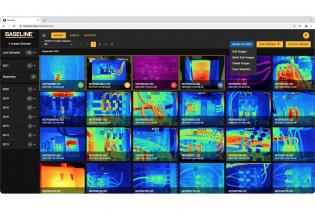

Fluke SmartView R&D Thermal Imaging Software

Thermal imaging software to analyze data and create reports from data your thermal camera.

Fluke Ti300+ Thermal Camera

Ideal for industrial preventive maintenance programs. Features LaserSharp™ AutoFocus and 320 x 240...

Fluke Ti401 PRO Thermal Camera

Choose the highest resolution thermal camera in its price range. The Fluke Ti401 PRO thermal camera...

Frequently asked questions for infrared thermal imaging cameras

What is a Thermal Camera?

A thermal camera is an inspection tool that captures infrared energy – radiation emitted from an object – and creates an image. Thermal cameras, also known as infrared cameras and thermal imagers, are ideal for industrial inspection. Maintenance, leak detection, and machine troubleshooting are all common applications.

What is a Thermal Camera Used For?

Thermal cameras can be used for a broad range of applications: building inspection, security, electrical maintenance, firefighting, gas detection, and beyond. Thermography is an especially powerful test method for uses in which:

- Remote inspection is essential for safety

- Damage or decay is expressed through temperature changes, such as in three-phase wiring

- Test objects/subjects are obscured due to poor visibility

What Makes Thermal Imaging Cameras Useful?

Some thermal imaging cameras can see up to 1km and beyond, but most can’t see through thick solid surfaces like walls.

What is Thermal Imaging?

Thermal imaging is the process of capturing infrared radiation and translating it into thermal images, or thermograms. Thermal imaging shows variations in temperature expressed in color. Powerful infrared cameras are incredibly sensitive, displaying heat in great detail with color gradients.

How Does Thermal Imaging Work?

Everything around us emits infrared energy – a heat signature. Thermal imaging works by measuring infrared energy and converting that data into electronic images that display surface temperature. An optical system focused infrared energy to a sensor array, or detector chip, with thousands of pixels in a grid. A matrix of colors corresponding to temperatures is sent to the camera display as a picture.

What is an Infrared Scanner?

An infrared scanner measures human temperature, often mounted for continuous monitoring and with a large display. Infrared scanning is a term most often used for human body temperature measurement. However, infrared scanners can also be used for applications like scanning machines, concrete, and buildings.

Choosing the Best Thermal Camera

The best infrared thermal imaging camera is the one the has the price point, ruggedness, portability, thermal sensitivity, and image resolution you need.

- Best for handheld inspections: Fluke Ti480 PRO Infrared Cameras are lightweight, handheld imagers with powerful sensitivity that make it easy to discover and diagnose issues.

- Best for research applications: Fluke RSE600 Mounted Infrared Cameras give you the power to stream thermal images via desktop software, connect to MATLAB and LabVIEW software, and perform R&D analysis.

- Best for industrial inspections: Fluke TiX580 Infrared Cameras are rugged handheld cameras with an easy-to-read 5.7 inch LCD display and the ability to capture high-resolution 1280 x 960 images.

Chat with ourFluke assistant

Hi, I'm your virtual assistant, I will do my very best to help you navigate all things Fluke related. You can ask me anything! I'm new and might make a few mistakes. For safe use of Fluke tools, refer to the product manuals, safety sheets, and your company's safety requirements. To speak with a person, visit our Contact Us or Talk to Sales page. For information on how we handle personal data, see our Privacy Policy.